Getting Results for Your Customer

The full saying is: "The proof of the pudding is in the eating."

My entire life, I've always heard the abbreviated version: "The proof is in the pudding." I understood the intent behind the phrase, but I never understood how that saying made any sense. I guess that, over the years, we all got used to the short version. Maybe due to our fast-paced lives or the internet or whatever we blame things on these days!

The proof of the pudding is in the eating. You have to eat the pudding to get proof that it's good. Well, duh!

Anyways, it got me wondering: If the proof of the pudding is any indication, what else have I been going about wrongly this whole time? That probably opens up a can of worms best left for another blog post (or twenty.)

But, in regards to MonMan, the HVAC/Electrical/Construction industry, what have we all been doing incorrectly all these years?

When a team member here at MonMan forwarded me some recent Air Handler test results, it got me thinking about pudding!

This person is the product manager for our custom air handler brand and has to face product testing all the time. For every single project she works on, she has to prove the product works as claimed.

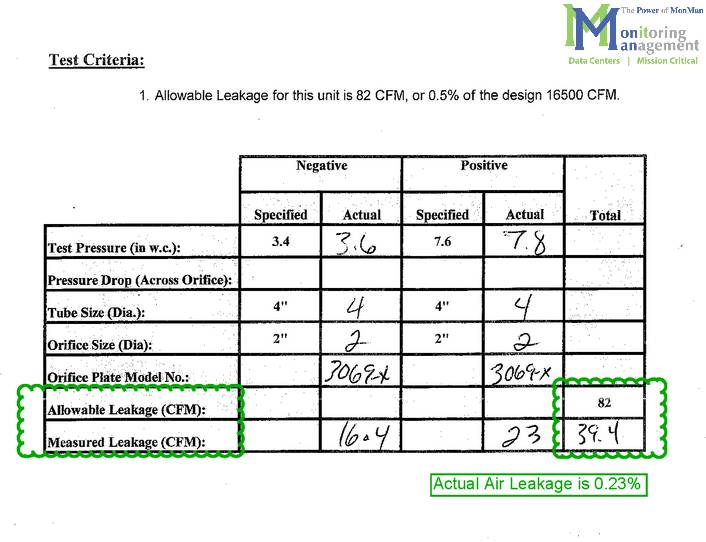

One of the big claims to fame is that we can install air handlers with less than 0.5% air leakage...guaranteed for the life of the unit. We achieve this without extra caulking, duct tape, or any type of temporary sealing method. This is important to our customers because air leakage is a major component of energy efficiency. Once you change out your lights for efficient LEDs, conserve water and turn up the thermostat a few degrees, where do you turn to get more energy efficiency?

We think the air handlers are a major source of energy inefficiency. They run 24/7/365 and are usually up on the roof or tucked away in some dirty mechanical room. Many air handlers lose 1 percent efficiency each year of operation. It's not uncommon for fairly new air handlers to leak 10%-15%. That is a huge energy hog.

If you could reduce the air loss of your air handlers to less than 0.5%, wouldn't it make sense to?

I don't care about the ingredients, what does it taste like?

In the HVAC industry (and most all industries, I suspect) too much attention is paid to buzzwords: new, proprietary, advanced, unique. What do they really mean? Facility managers, engineers and service technicians don't have time to play around with buzzwords!

And that's why the test results that made their way to my desk got me so excited! They are the proof that we have been doing the right thing, and that our customers are getting true value.

If we could guarantee 0.5% air leakage or less, for the life of the unit, that'd be pretty great, right?

What if the air handler only had 0.23% air leakage?

Well, you immediately see how that unit is more efficient than anything else out there, and that's going to translate directly into energy savings for the customer.

But it's the part that goes unspoken that is perhaps even more important.

How do you make an air handling unit with 0.23% air leakage? You start with a company that's 50 years old, with a unique corporate culture where feedback from the production line easily flows to the top. You add in industry-leading construction methods (quality, not compromises). You only use top-quality components like structural aluminum, interlocking flanges, foam-filled panels and a foam-filled structure, double gasketing and more.

Want to see us in action? Check out this video showing a custom AHU replacement.

The result: An air handler that is so energy efficient compared to the unit it replaced, it will literally pay for itself within its lifetime.

Over the years, I have found that talking to a customer about quality: stronger metal, tighter joints, thicker foam insulation, better gaskets, is great, but often that doesn't directly connect them to the desired end result: a better, more efficient, longer lasting product.

Some new AHUs can get close to 0.5% air leakage, but how are they doing it? Are they using extra cases of caulk (yes, it happens all the time, and the contractor is stuck with labor hours to do it.) Are they using duct tape to cover holes during testing? (yes, I've seen it before and took pictures!).

If you are looking for a little proof of the 0.23% air leakage test result, see the below, monochromatic, non-snazzy test report:

We really shine on AHU replacements. When you tear out an old air handler that is leaking 15% or more, as was the case recently, and replace it a new unit that has an ultra-efficient unit with 0.23% leakage, you save money. $6,862 per year to be exact. And that's for a small 16,500 CFM AHU and a low electrical rate of $0.07/kwhr. For an air handler of a more common 40,000-50,000 CFM size, you will save tens of thousands of dollars per year, just because the unit leaks less!

So, if you're in the HVAC industry, take a look at our air handlers. If you're in another industry, and you provide a product or service, think about ways to prove to your customers the results you have been claiming all this time. Put the test results in front of them. Don't let them ignore it. Make the data irrefutable. Get their attention. Then, customer service the heck out of them!

You see, buzzwords are great. They look good in articles, on websites and in the brochures. But we live in an over-saturated world. Everybody, and I do mean everybody, claims theirs is the latest and greatest. Buzzwords have lost their meaning. Focus on providing true value to your customers, and prove to them you can do it!